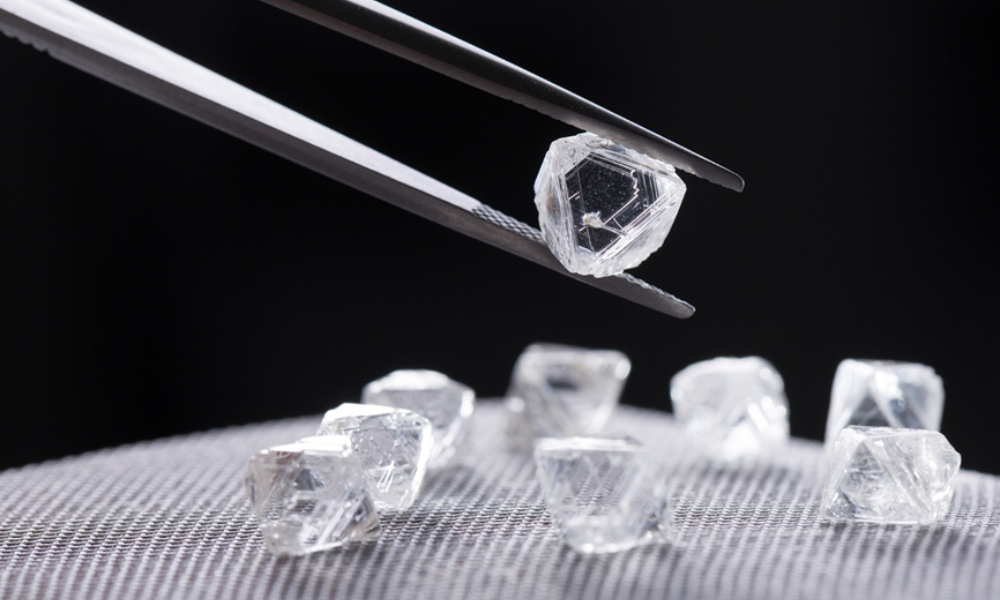

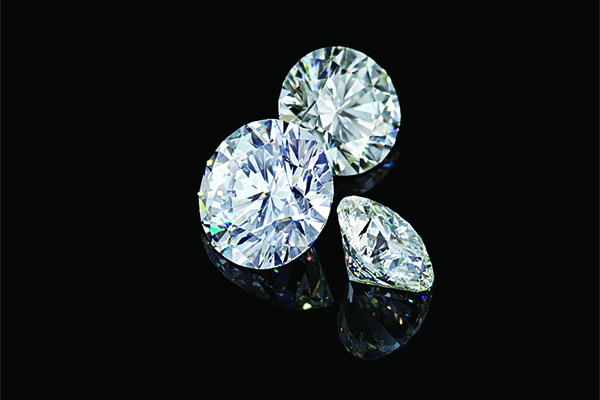

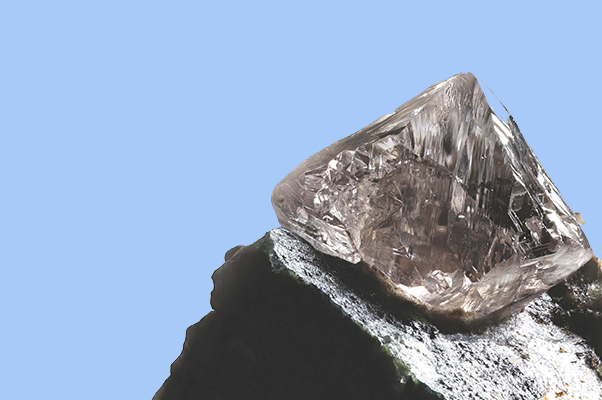

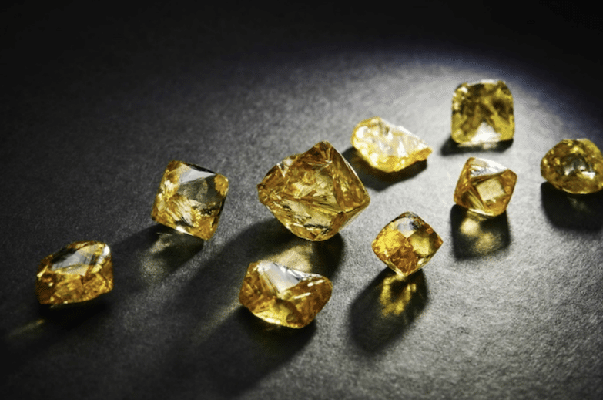

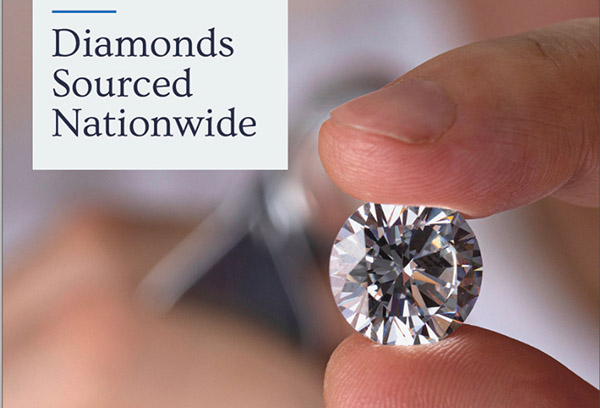

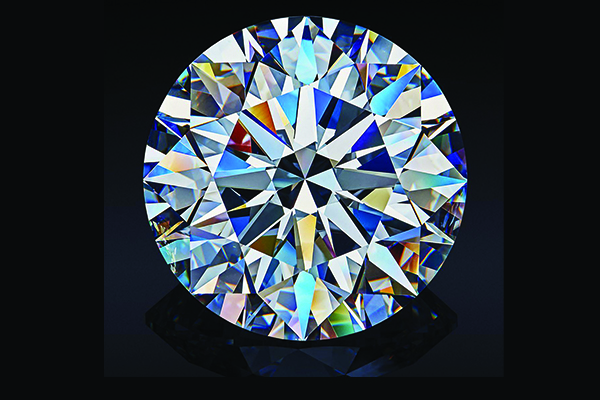

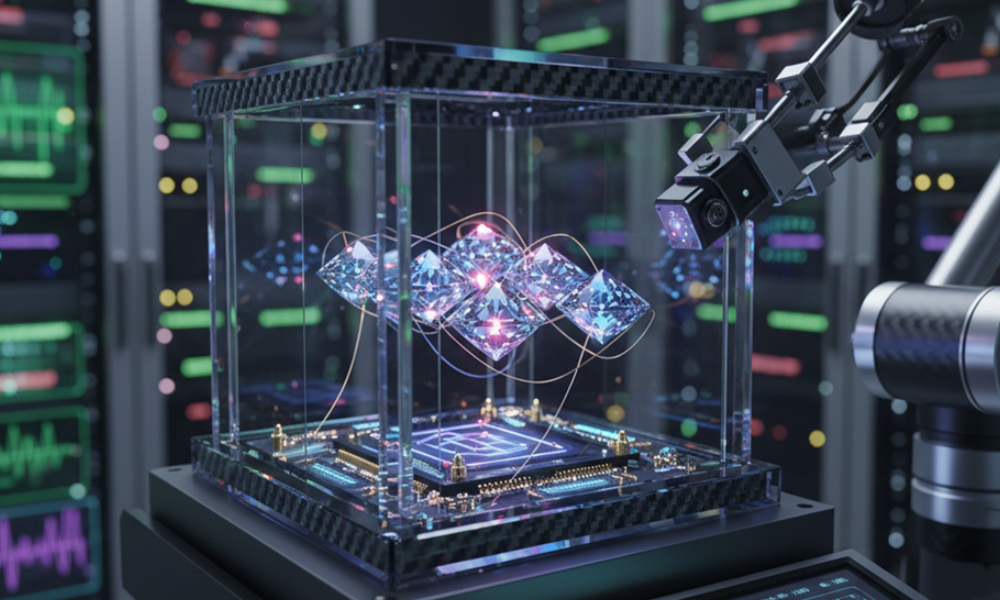

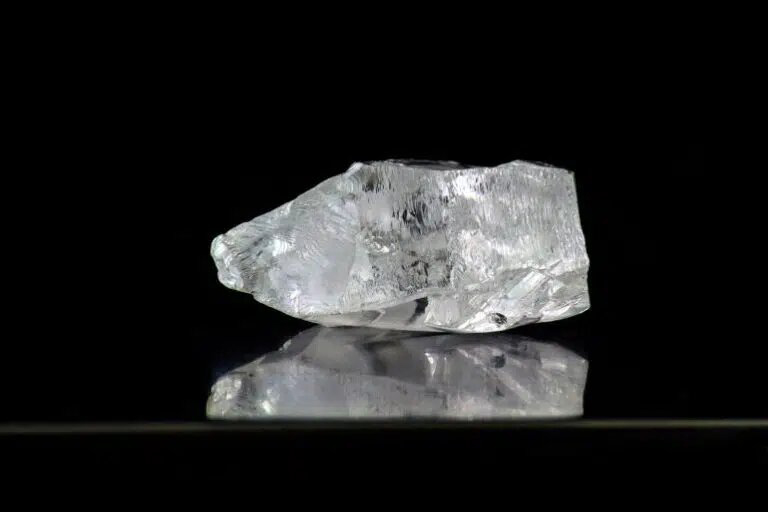

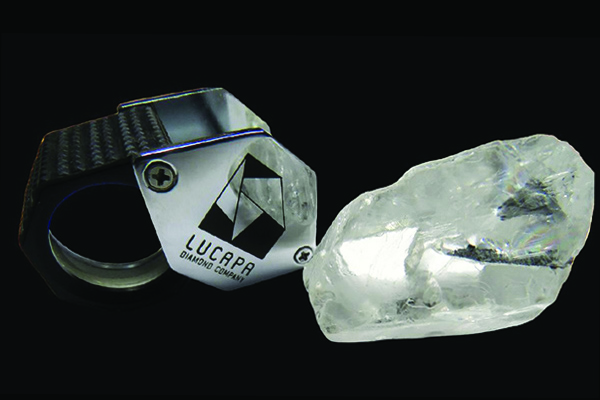

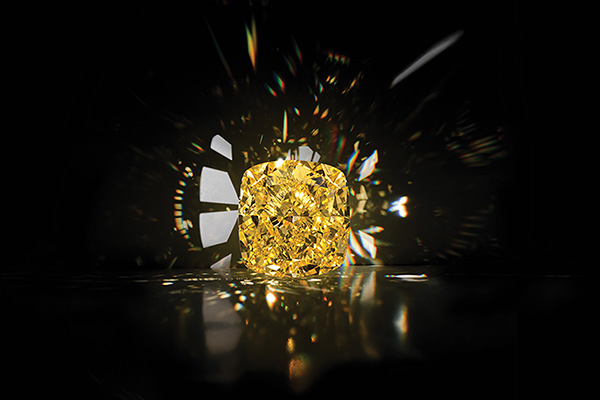

The Smolensk-based Kristall plant (part of Alrosa) has automated diamond cutting processes. This innovative approach reduces the labor intensity of the cutting operation by up to 80%, speeds up diamond production, and reduces the labor costs of cutters, while maintaining the highest precision—the quality standard of the “Russian cut.”

The Smolensk-based Kristall plant (part of Alrosa) has automated diamond cutting processes. This innovative approach reduces the labor intensity of the cutting operation by up to 80%, speeds up diamond production, and reduces the labor costs of cutters, while maintaining the highest precision—the quality standard of the “Russian cut.”

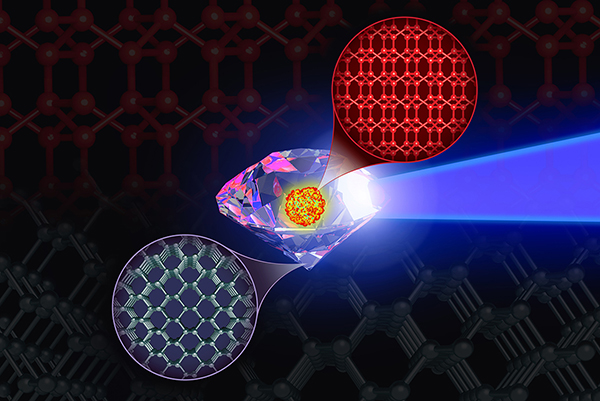

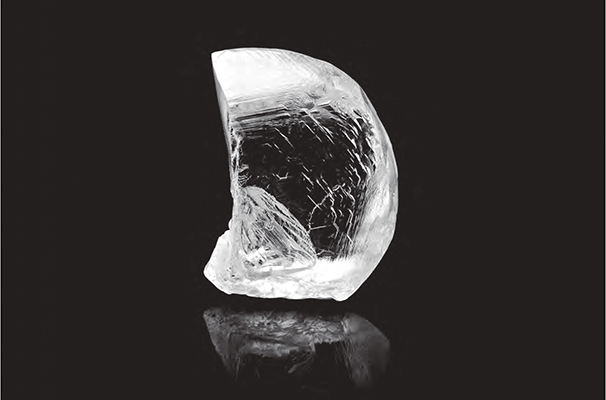

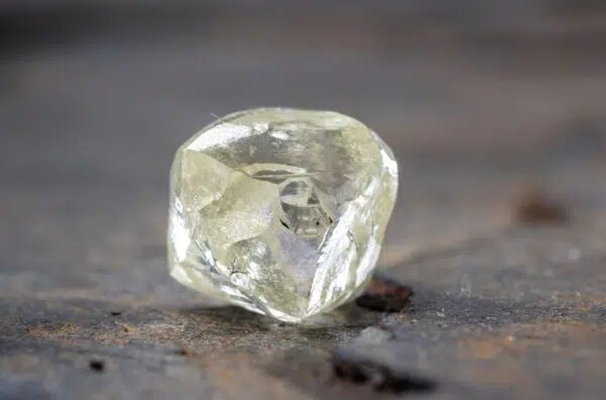

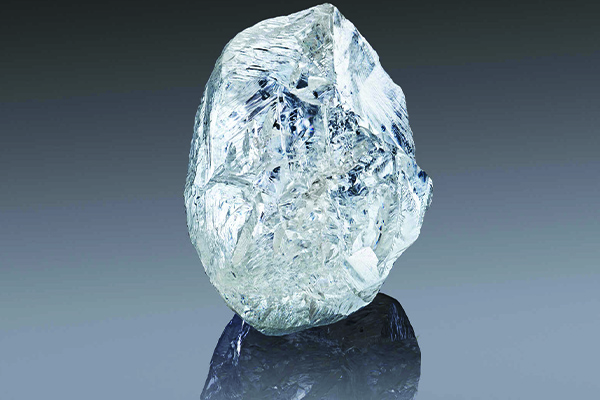

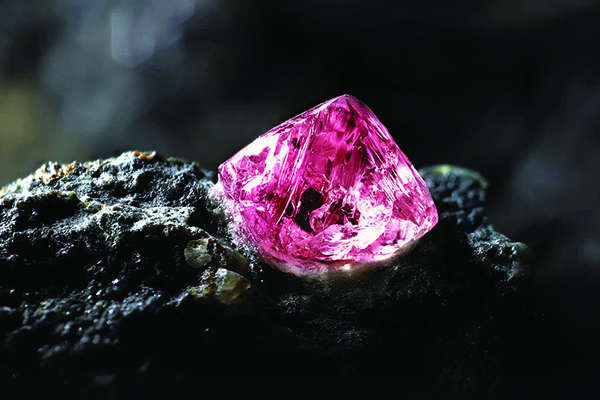

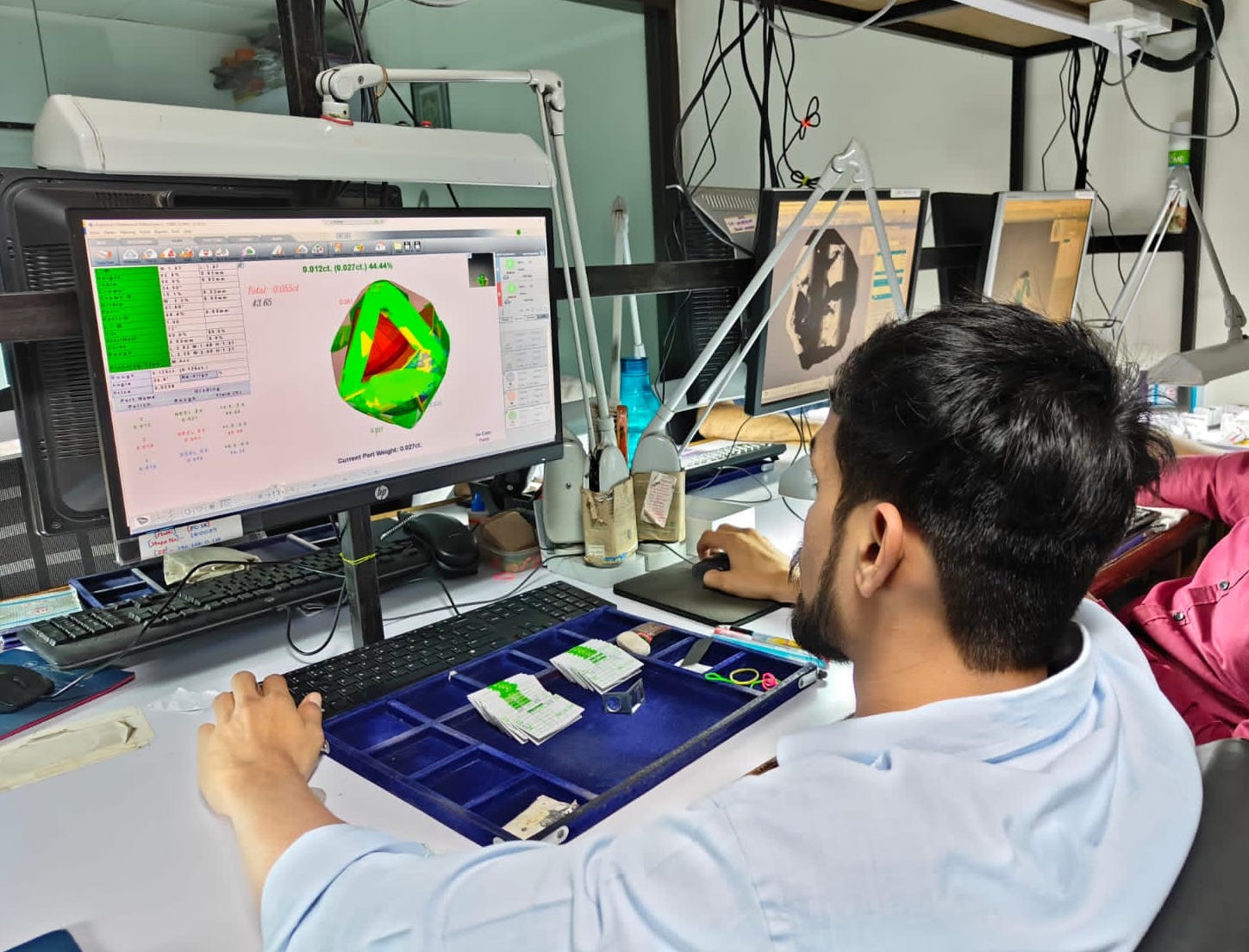

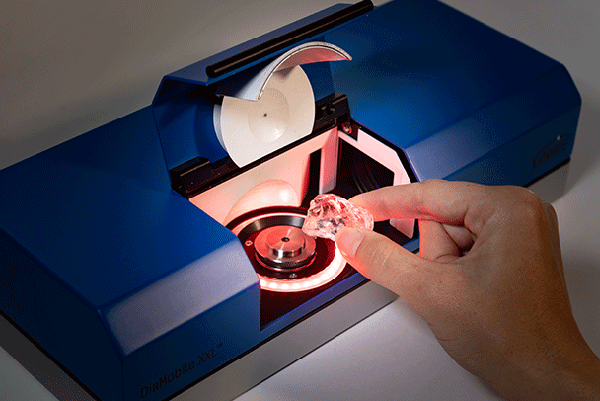

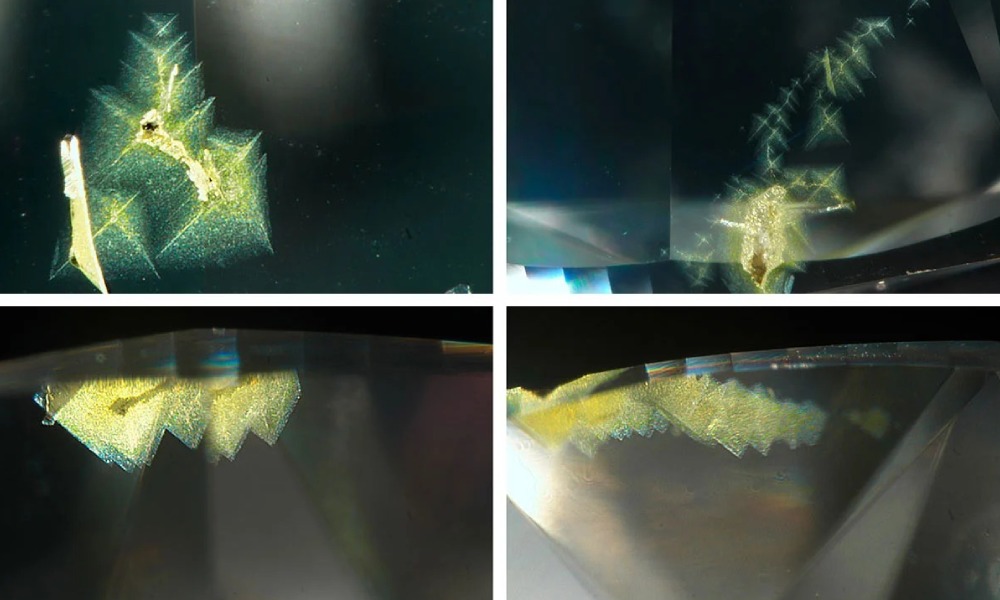

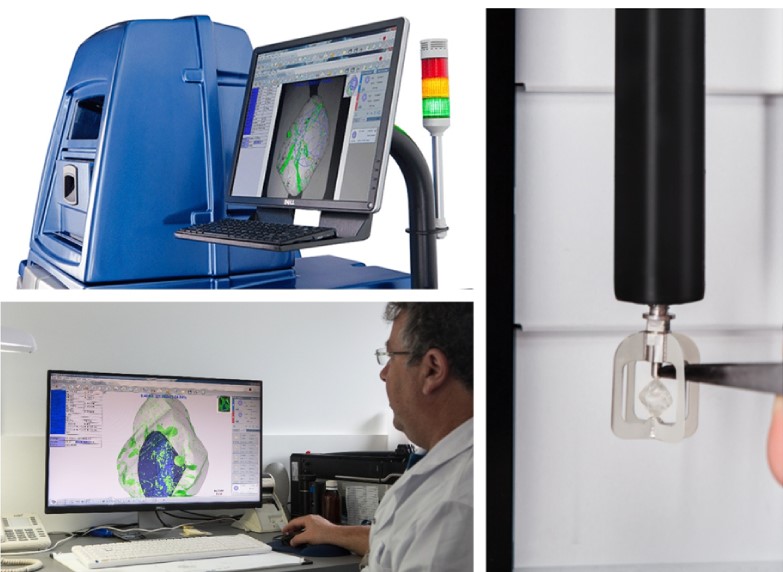

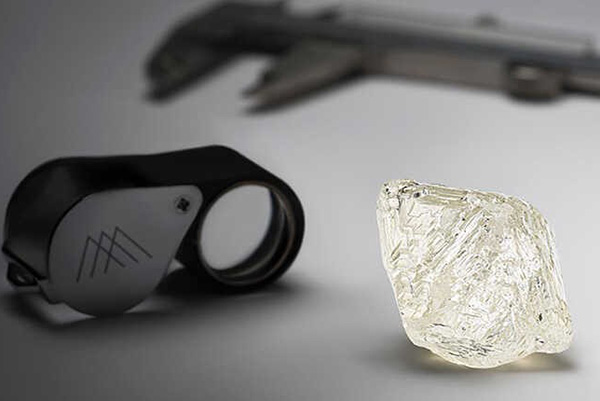

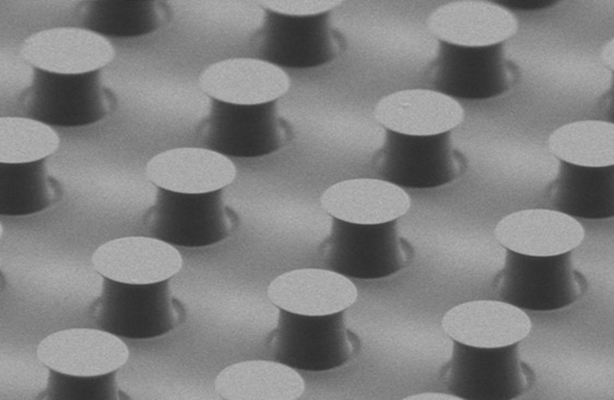

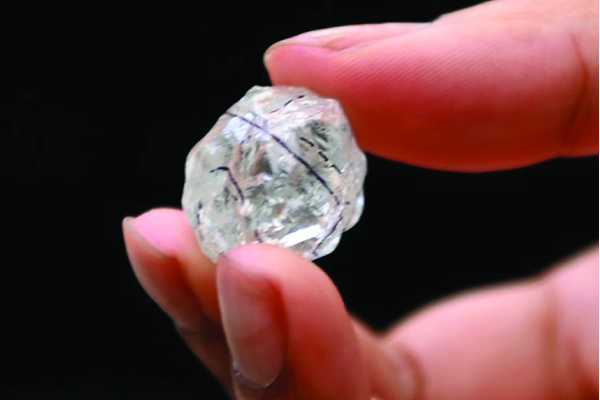

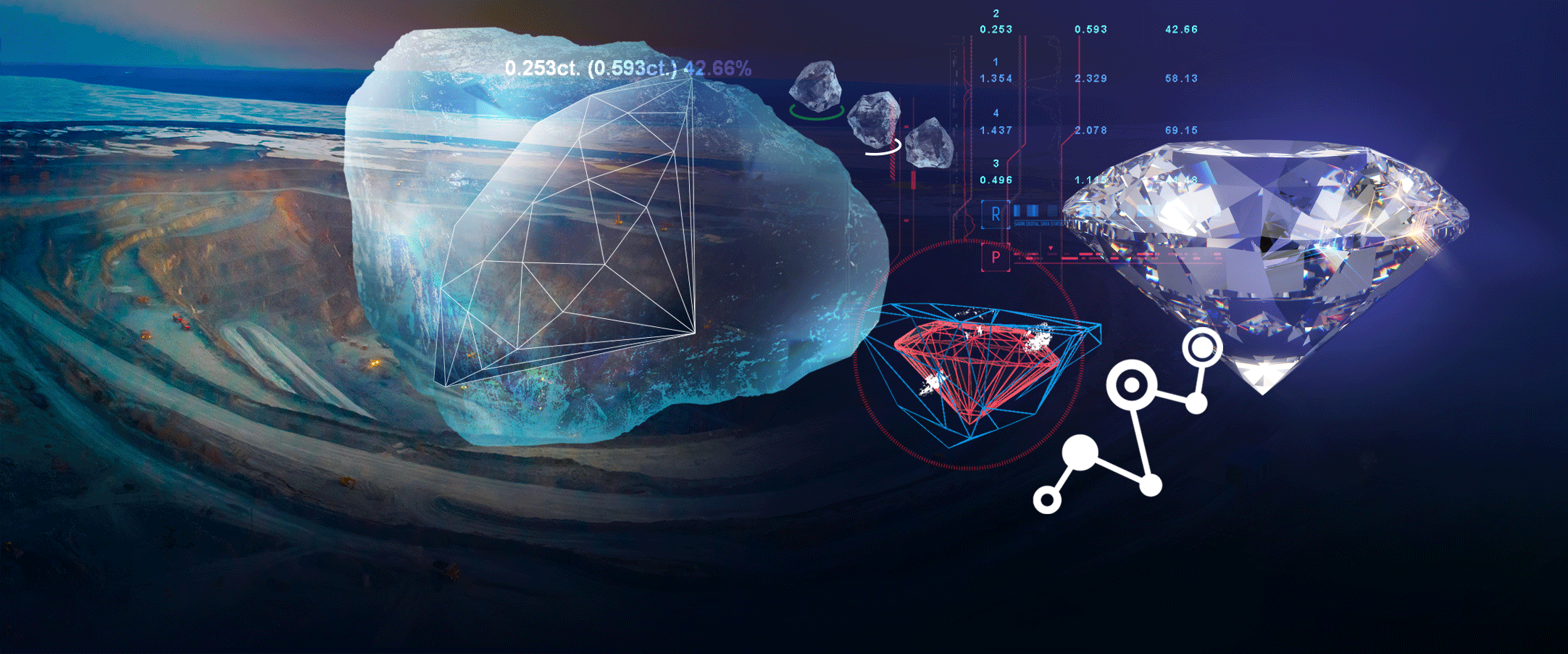

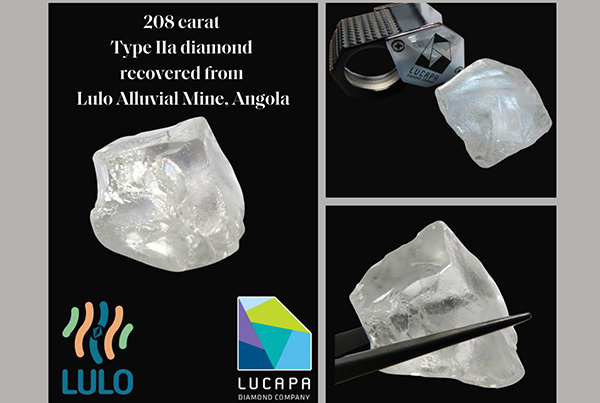

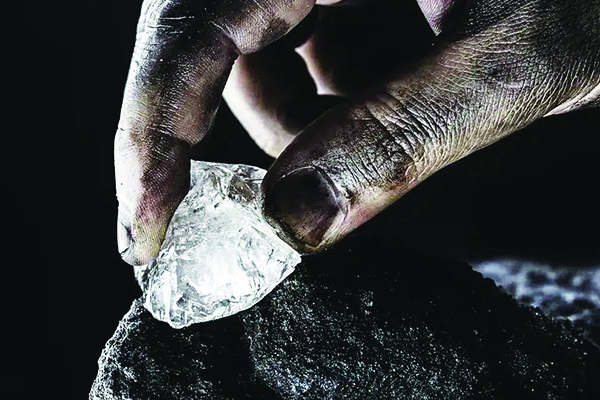

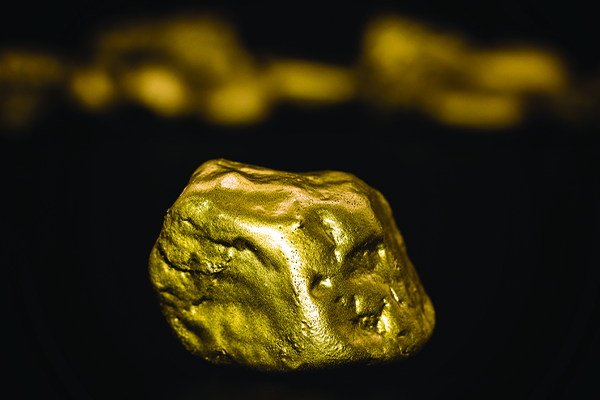

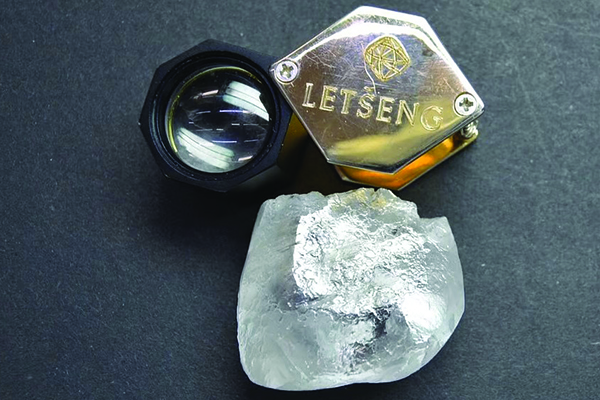

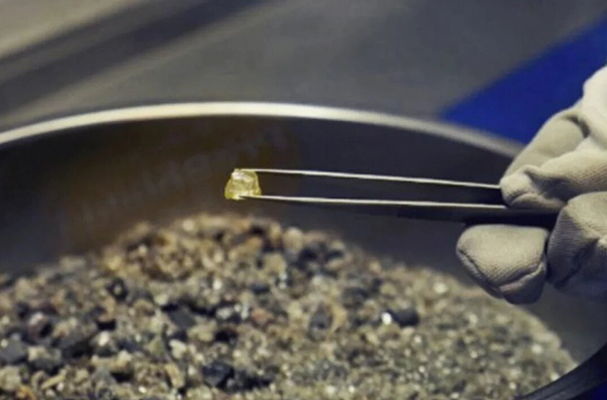

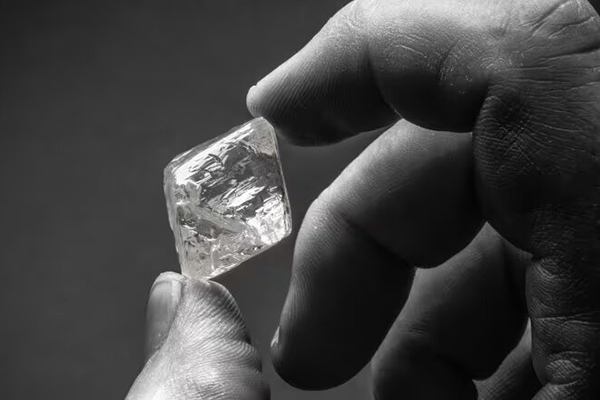

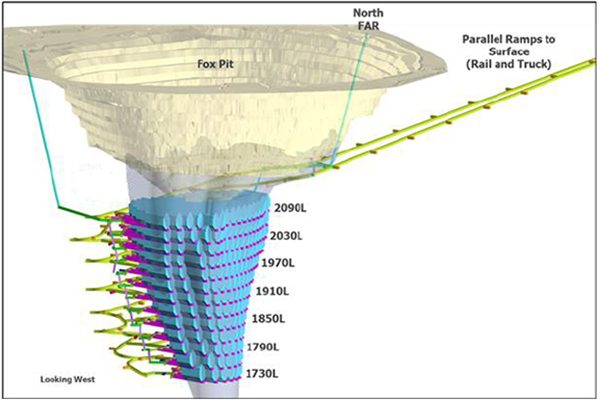

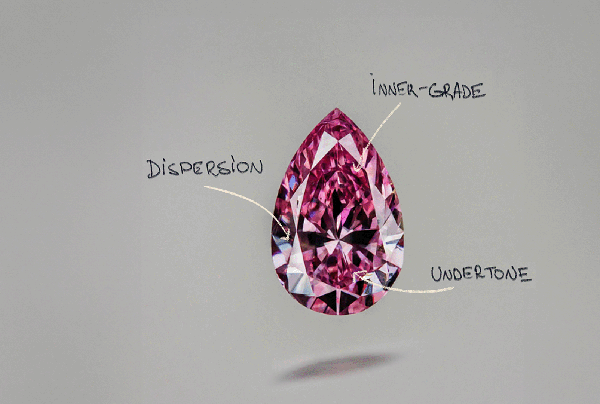

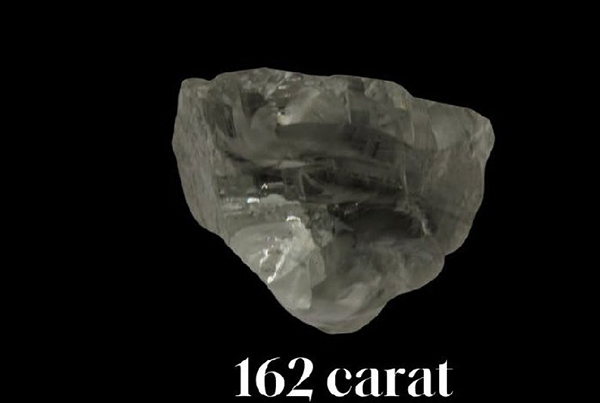

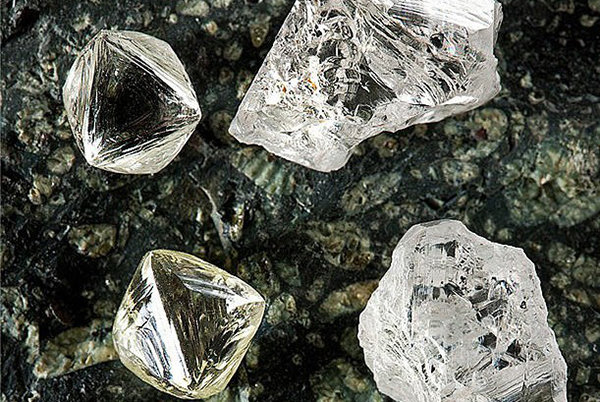

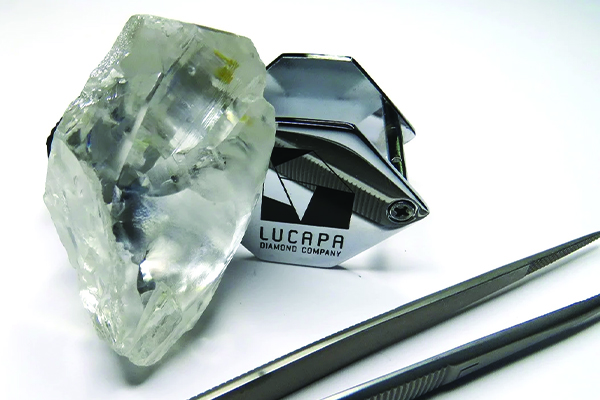

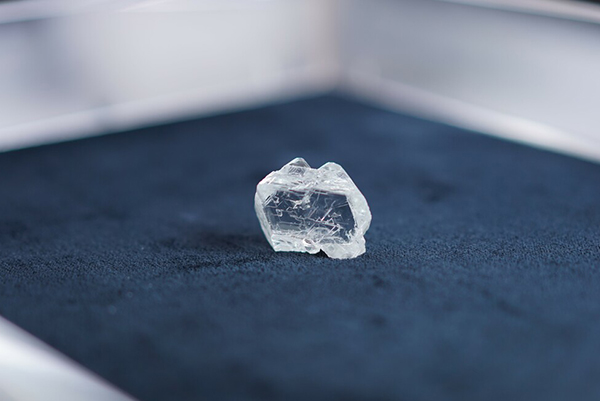

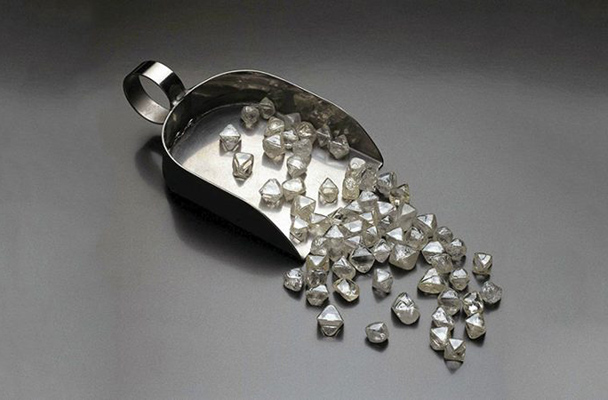

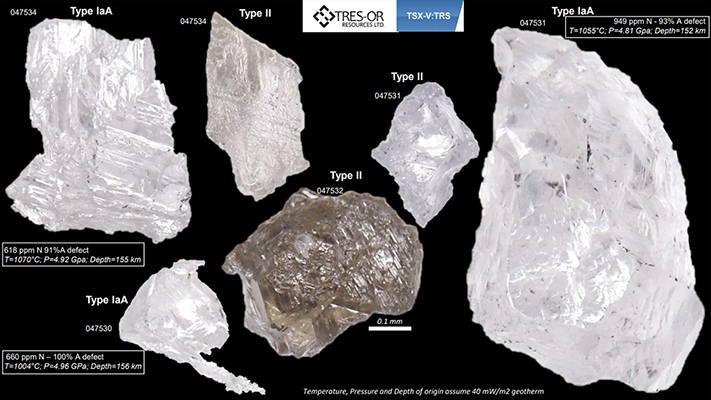

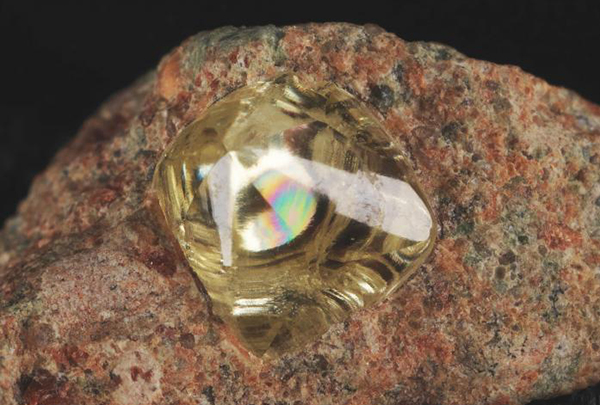

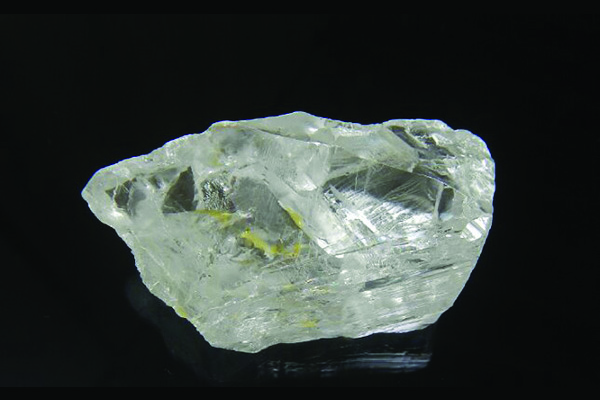

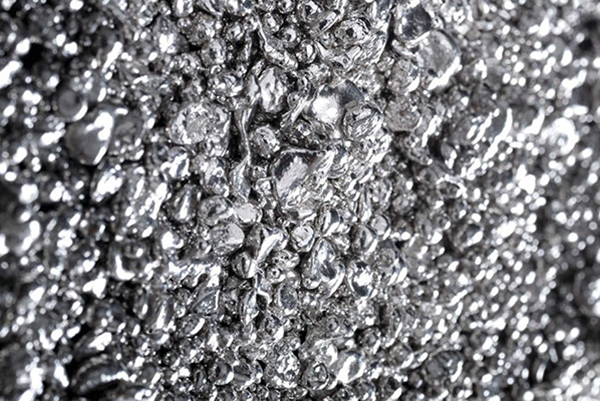

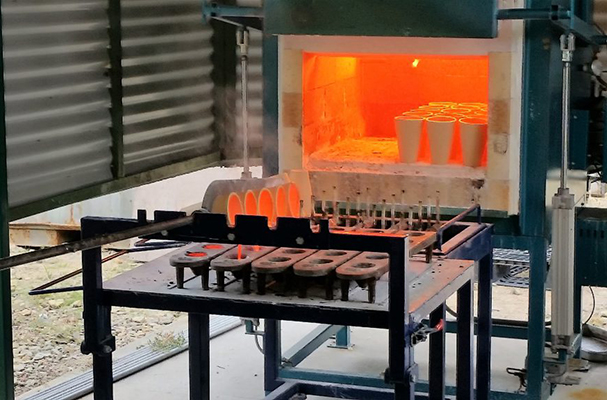

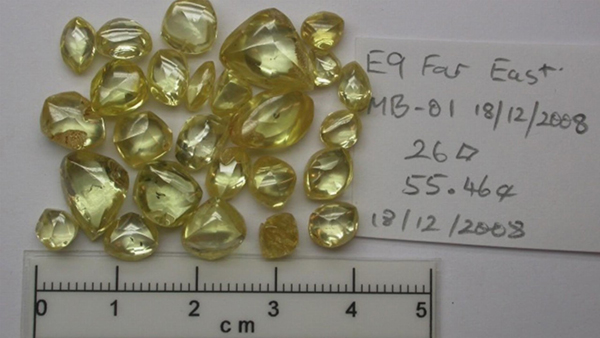

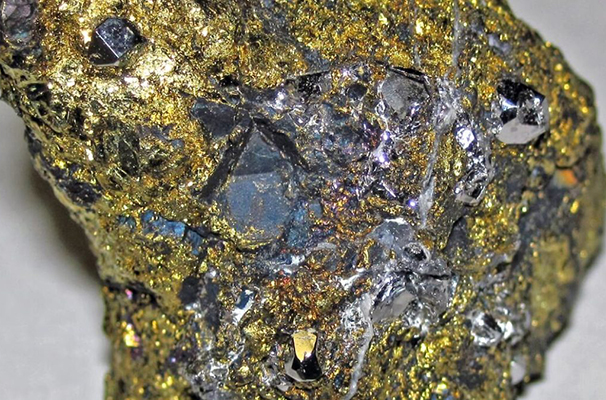

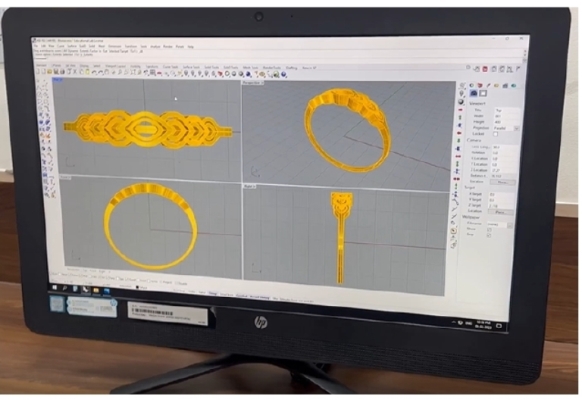

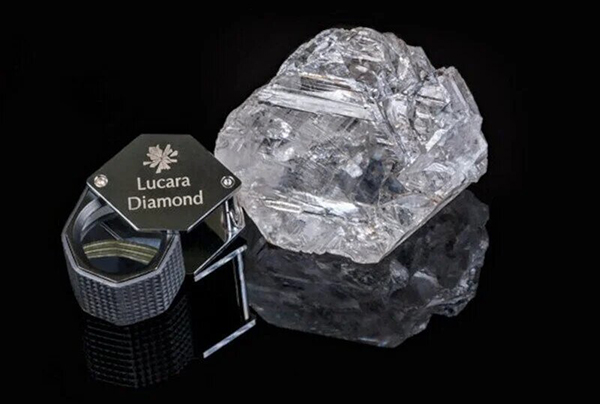

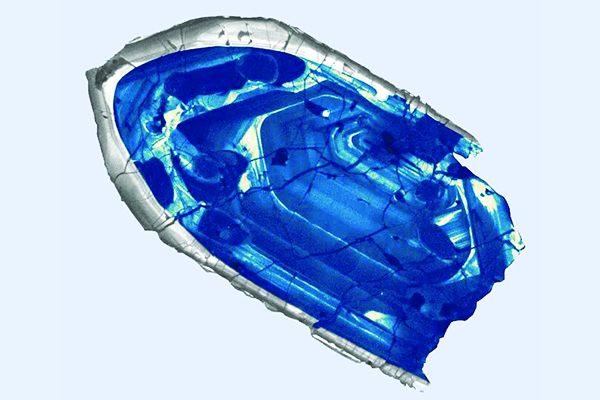

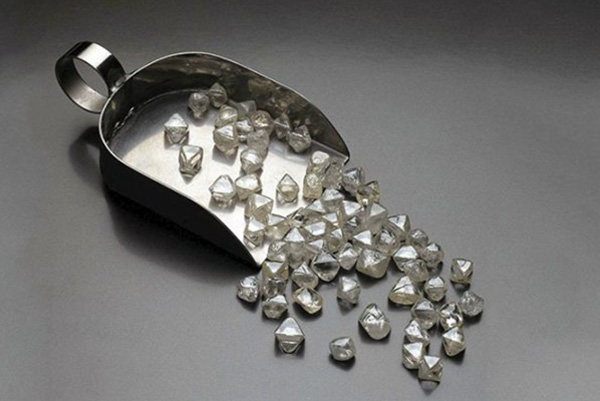

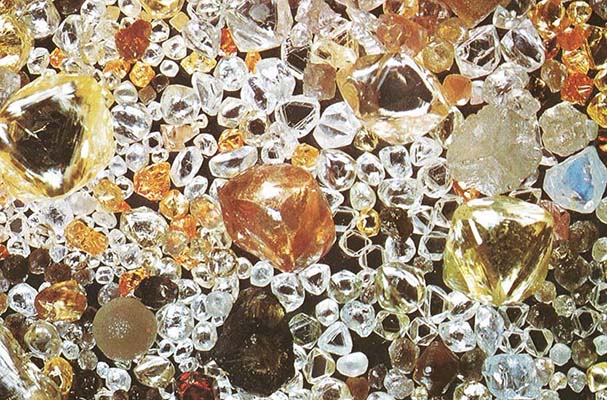

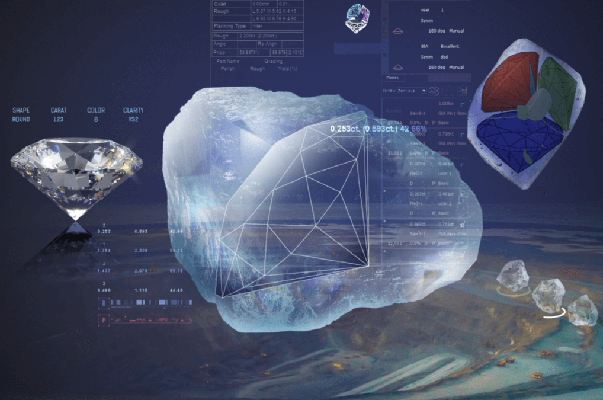

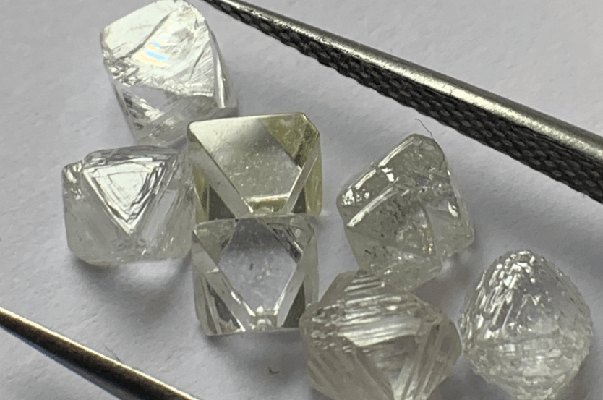

Automation has been implemented at several stages of the production chain. First, machines scan the diamond to create a precise 3D model of its external and internal structure, identifying all possible inclusions and features formed within the mineral deep within the Earth.

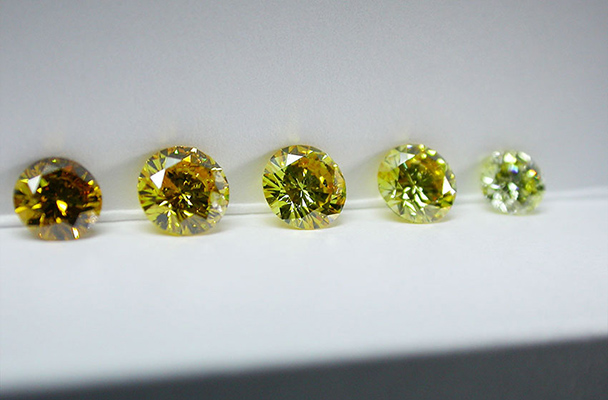

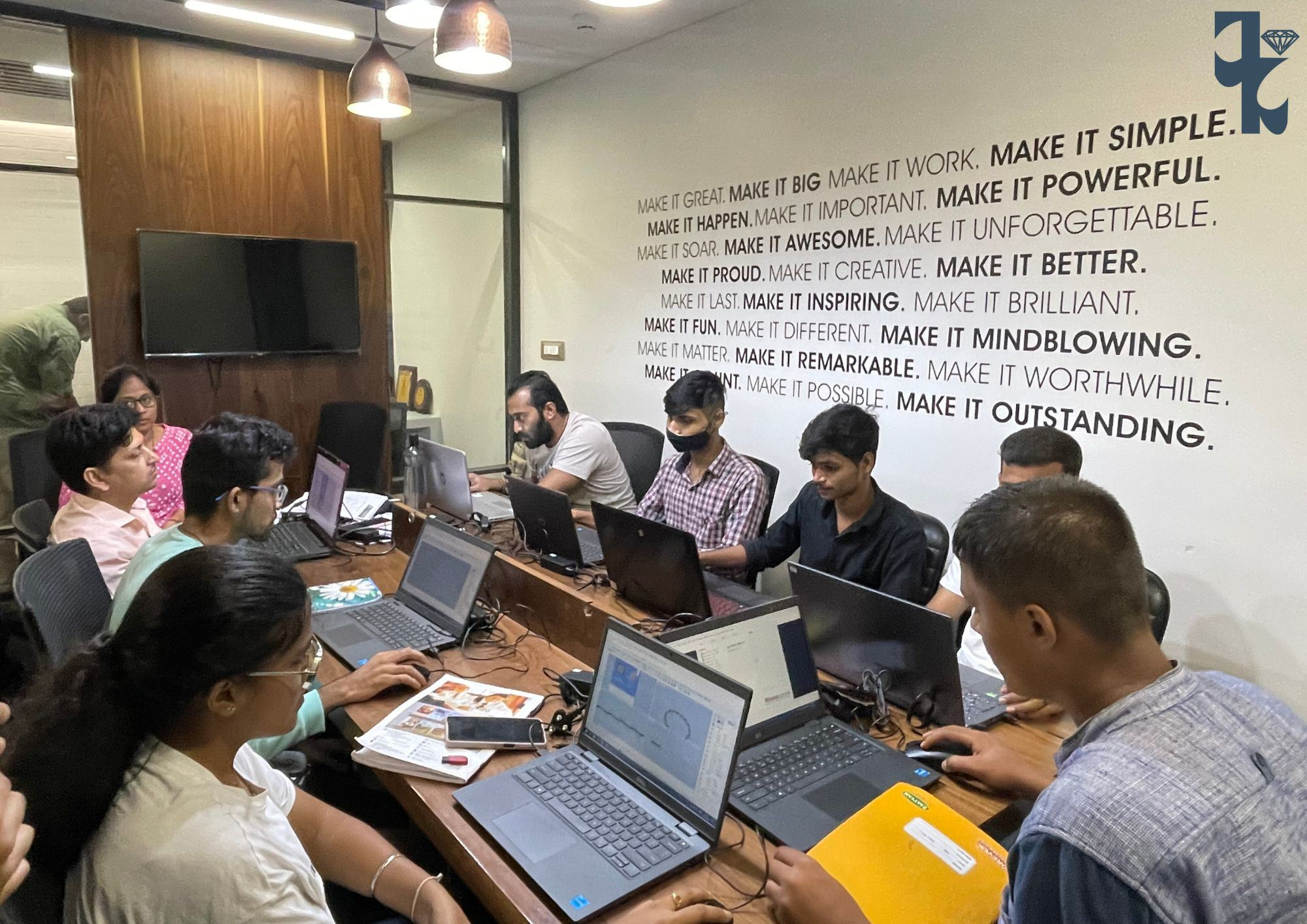

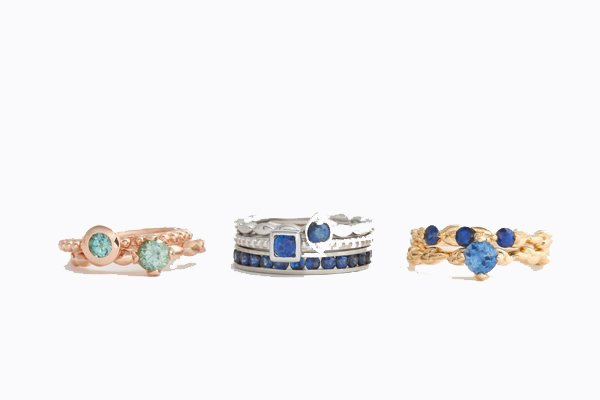

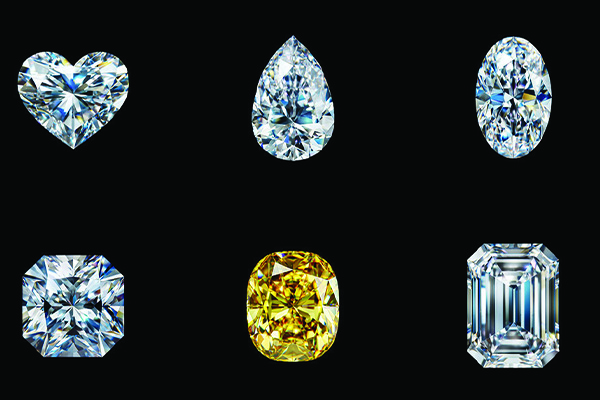

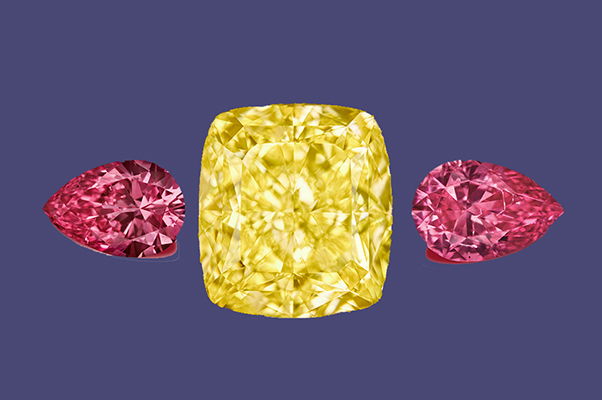

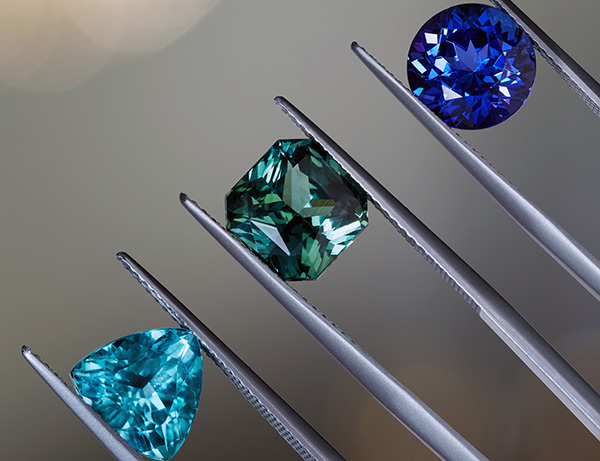

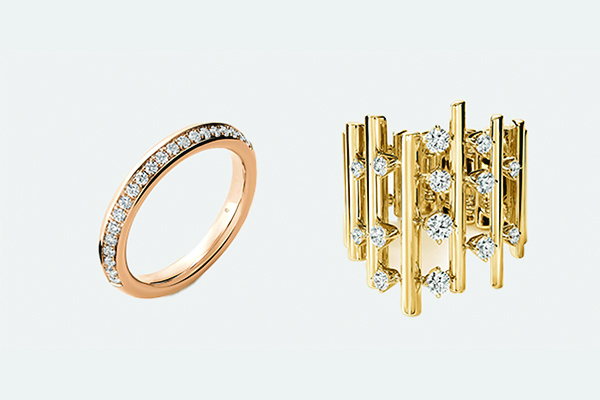

Based on the obtained data, a digital model of the diamond is created, offering dozens of options for producing one or more diamonds with different cut shapes and other parameters. Specialists then select the optimal option, which will yield the highest market value for the cut diamonds.

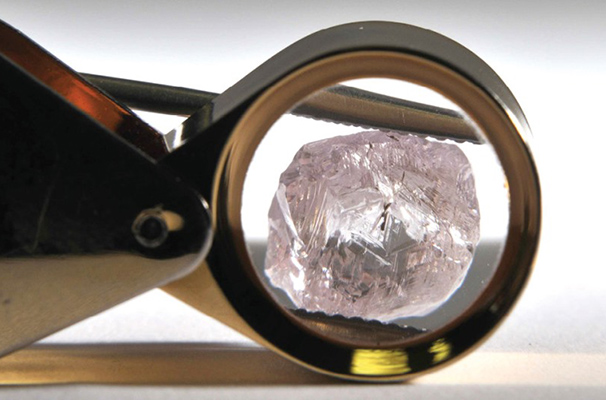

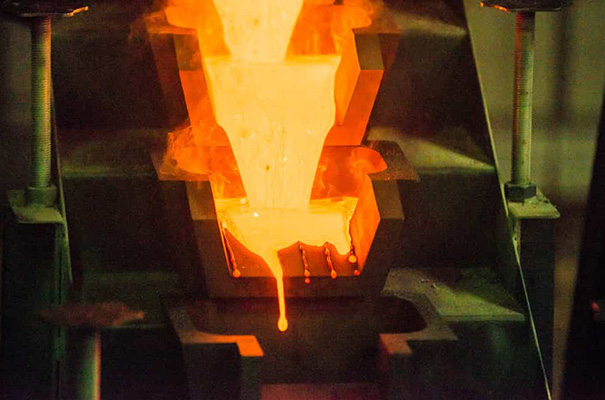

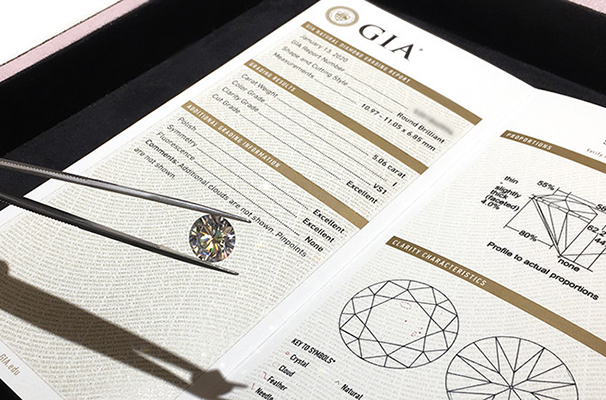

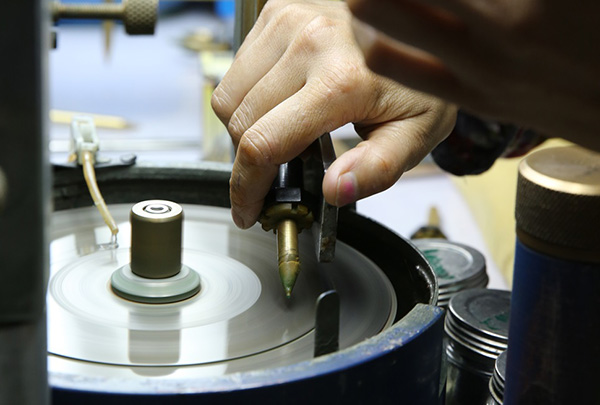

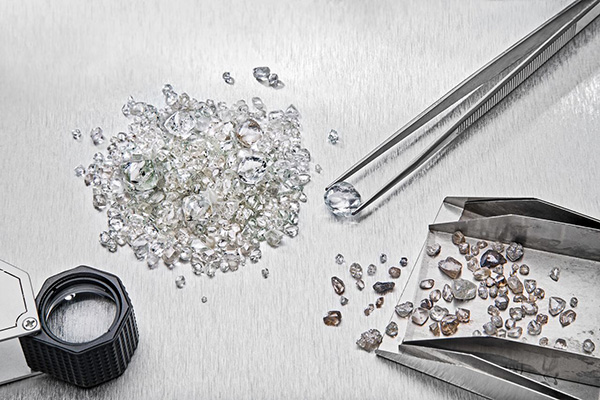

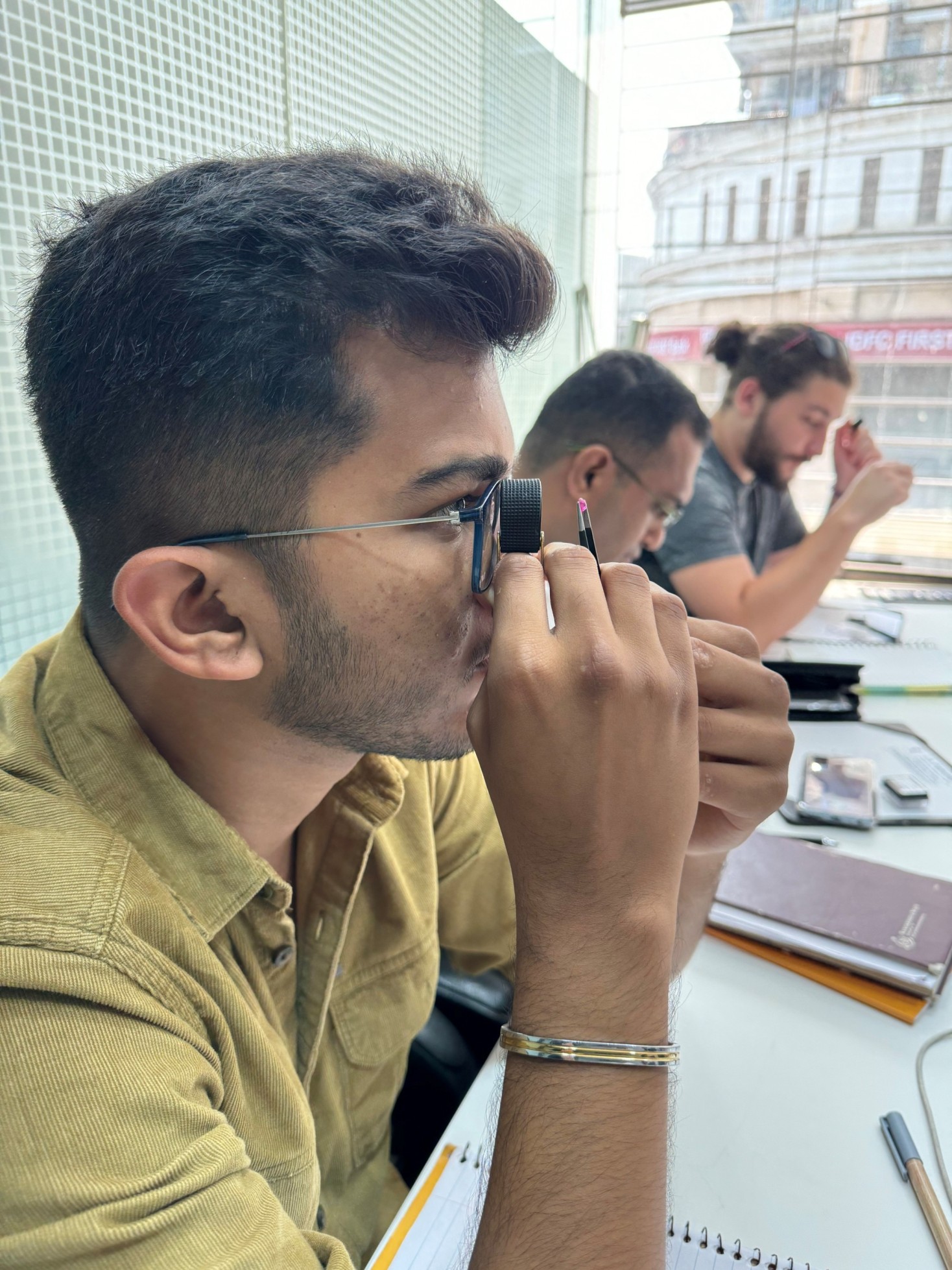

Next, the diamond undergoes automated laser cutting and laser shaping. After this, the most crucial stage remains, entrusted only to the hands of Kristall’s master craftsmen. The diamond cutters complete the cutting process, achieving the highest precision and finesse.

During the hand-cutting process, they are assisted by three technological assistants: a scanner for parameter control, a device for online polishing quality control, and a navigator that helps maintain the angles and facet shapes of the future diamond masterpieces.

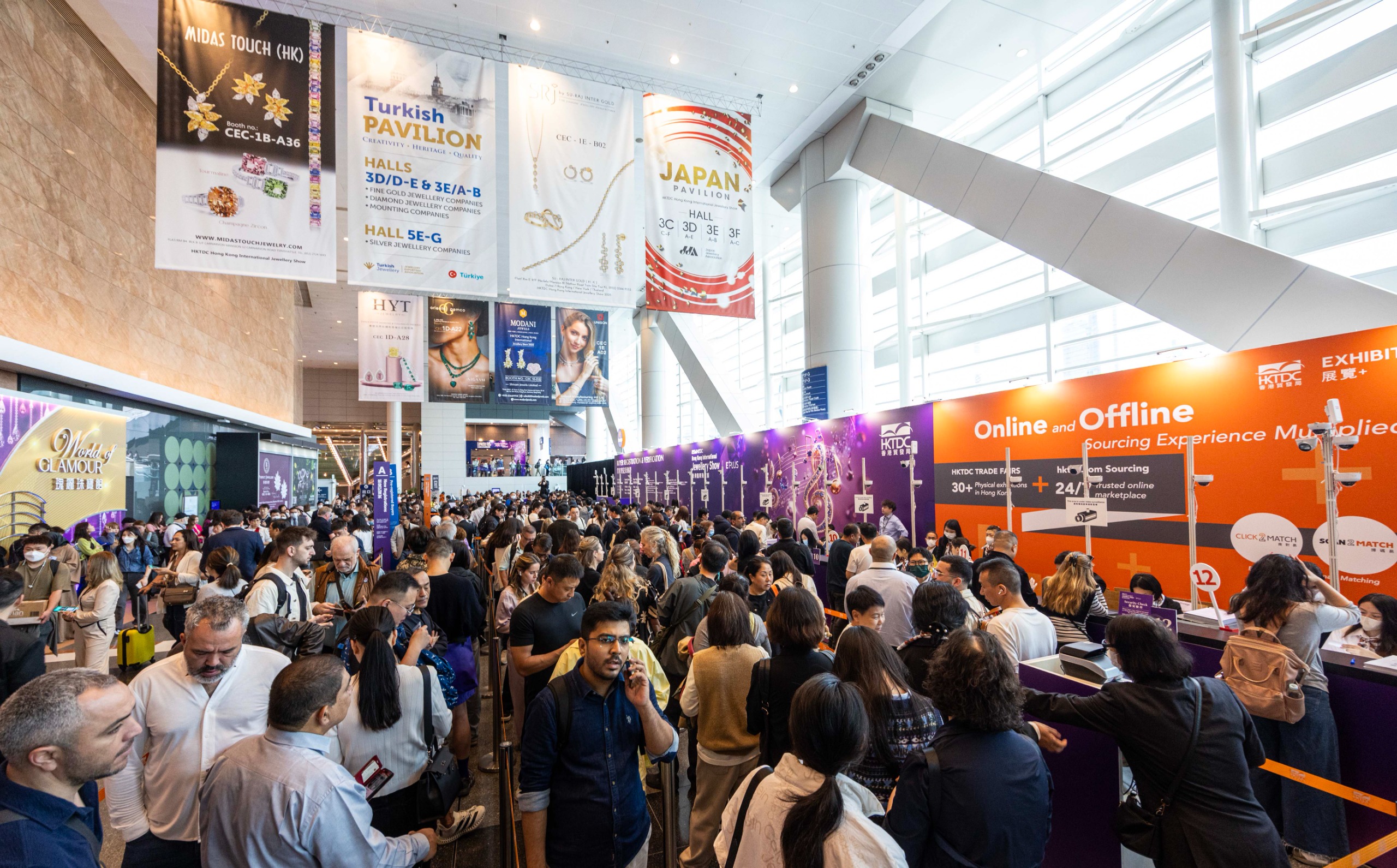

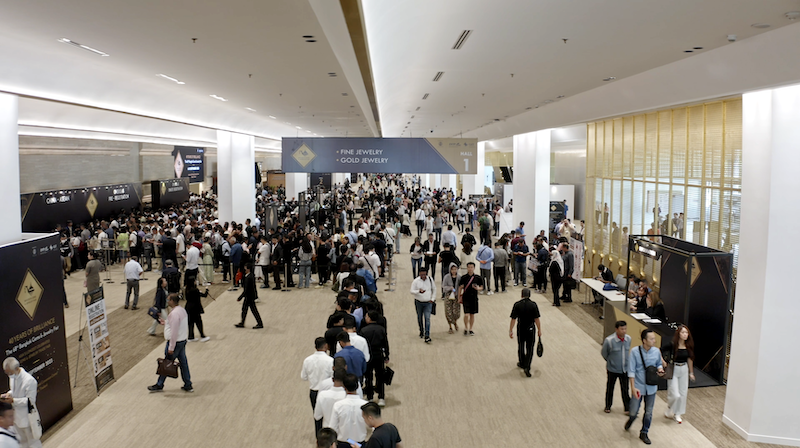

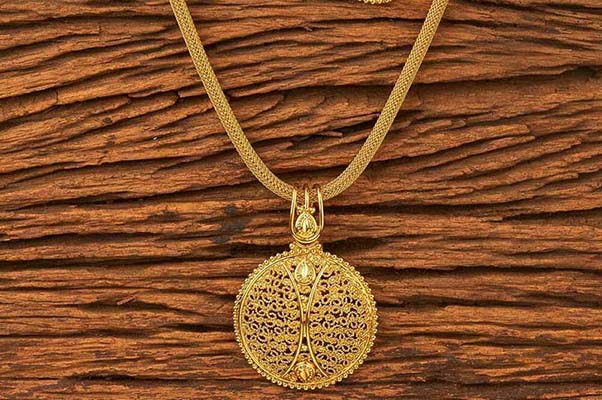

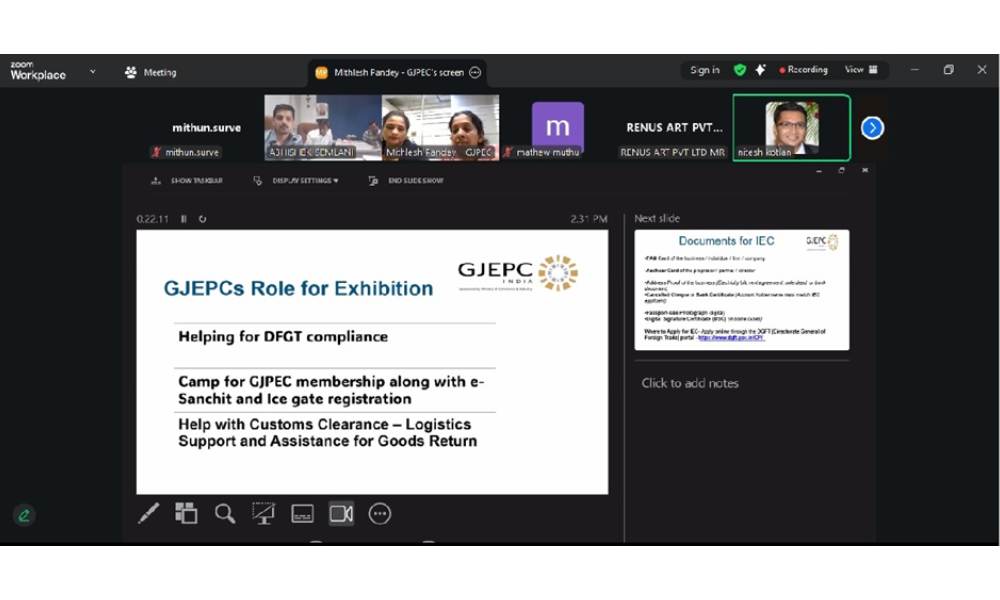

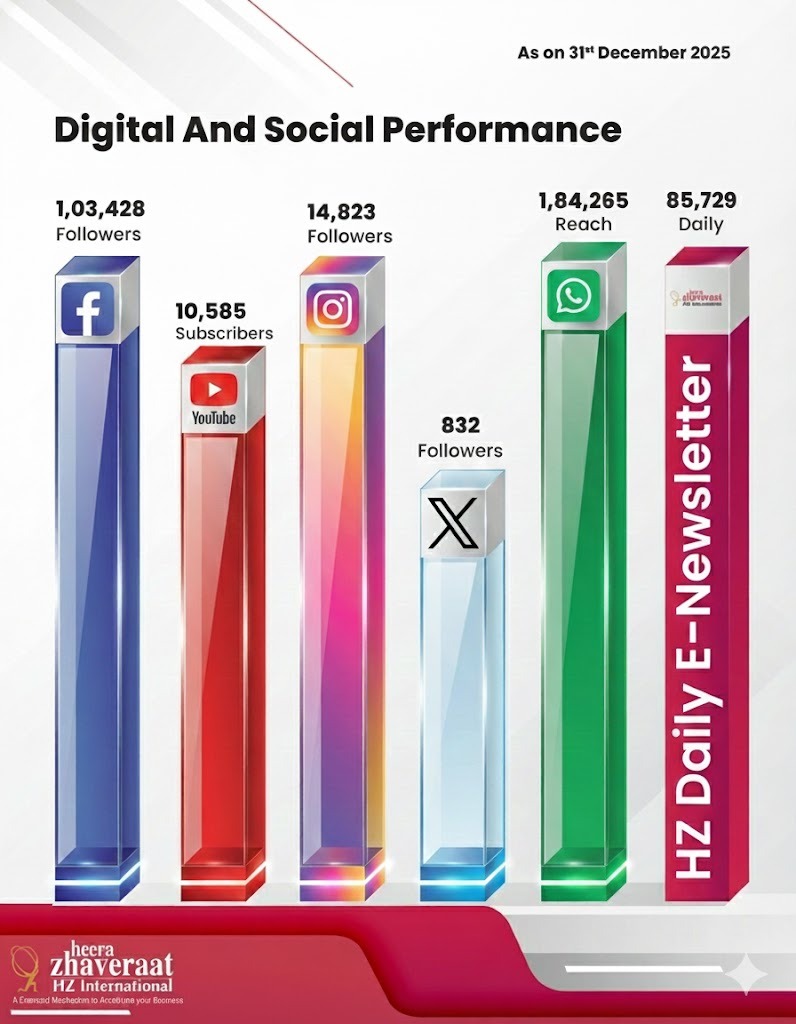

Offical Facebook account of heerazhaveraat.com, homepage for Trade News, Articles and Promotion of D

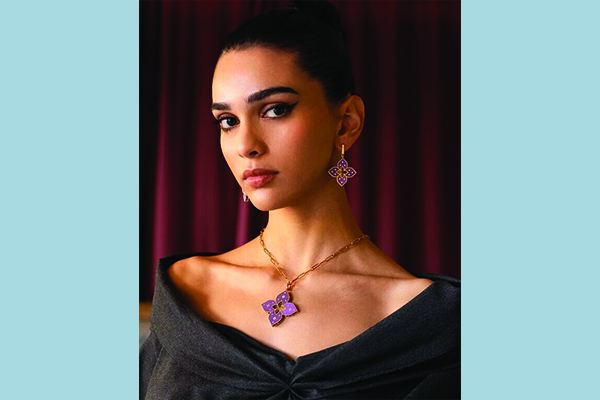

Heera Zhaveraat (HZ International) A Diamond, Watch and Jewellery Trade Promotion Magazine provide dealers and manufactures with the key analytical information they need to succeed in the luxury industry. Pricing, availability and market information in the Magazine provides a critical edge.

All right reserved @HeeraZhaveraat.com

Design and developed by 24x7online.in